Hydraulic Stuffing Boxes

The Hydraulic Slickline Stuffing box serves two purposes; guiding the slickline from the bottom hay pulley into the top of the lubricator rigup and containing well pressure whilst the slickline is either moving or stationary.

Product summary

The Hydraulic Slickline Stuffing box serves two purposes; guiding the slickline from the bottom hay pulley into the top of the lubricator rigup and containing well pressure whilst the slickline is either moving or stationary.

The Hunting hydraulic slickline stuffing box contains well pressure whilst the slickline is either moving or stationary and also guides the slickline from the bottom hay pulley into the top of the lubricator.

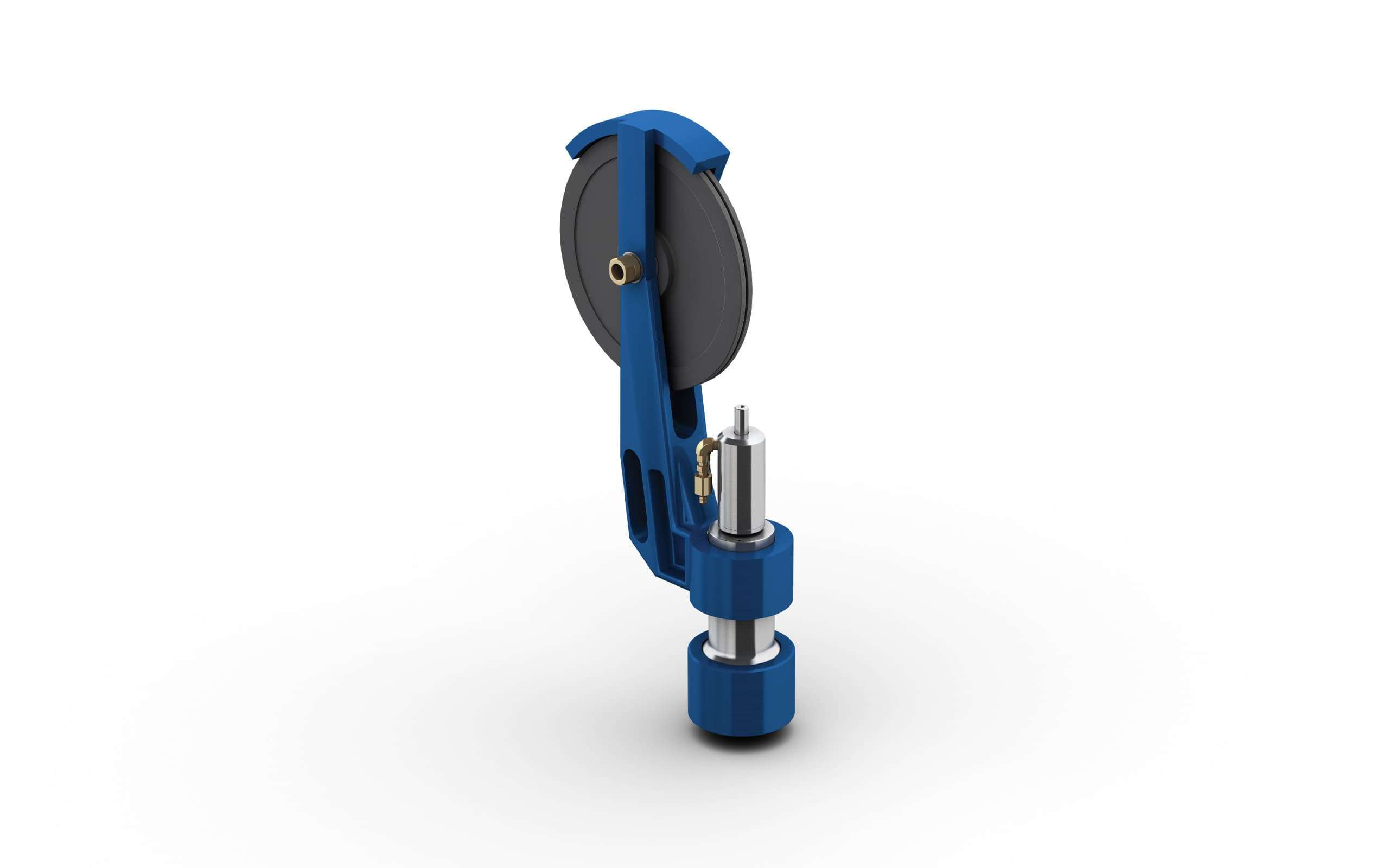

Slickline is passed over the sheave wheel and down through a hydraulic packing stack within the stuffing box body. Upper and lower bushings are provided to ensure that the slickline is guided into the centre of the packing stack. The hydraulic packing stack can be compressed from a safe distance should the packing leak due to wear.

The Hunting design philosophy is to create Stuffing Boxes that are rugged and reliable, whilst being as light and user-friendly as possible.

To avoid damaging expensive slicklines, internal components that are in contact with the wire are manufactured from brass, however other materials can be specified. A ball check valve is provided to prevent the escape of well fluids in the event of the slickline breaking.

The standard sheave bracket assembly is made from high quality castings, a composite or aluminium sheave can be selected. Free movement of the sheave and bracket is enabled by high quality taper roller bearings and each assembly is supplied with load test certification.

The sheave is either manufactured from composite or aluminium, depending on the application. It is available in 16-inch and 20-inch diameters to suit all slicklines up to 0.160-inches and each assembly is supplied with load test certification.

Stuffing boxes are available to suit almost any pressure and any union size, however we will supply equipment to suit customer’s specific requirements.

Features

Guides the slickline from the bottom hay pulley into the top of the lubricator rigup

Contains well pressure whilst the slickline is either moving or stationary

Upper and lower bushings ensure accurate alignment into the centre of the packing stack

Brass internal components prevent slickline damage

Sheave and bracket made from high quality castings

Ball type check valve used instead of traditional blow out plunger

Benefits

Light and User Friendly

Materials Used Avoids Damage

Hard wearing and reliable

Excellent seal characteristics

Elastomers options available to suit specific applications

Assembly supplied with load test certification